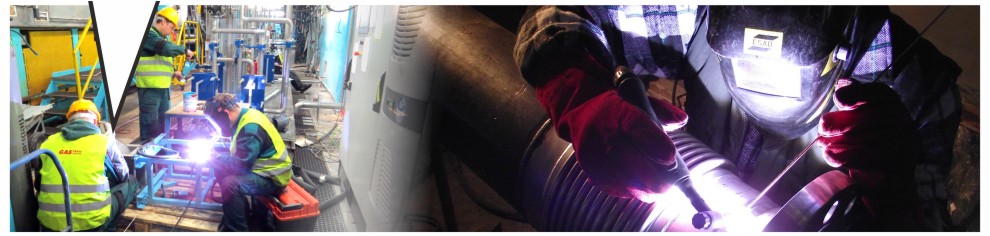

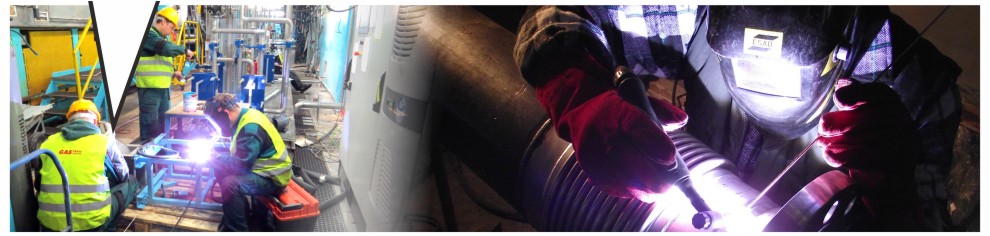

Manual Metal Arc Welding (MMA)

Arc welding, sometimes called manual metal arc welding (MMA), is a method for binding metal to metal by using electricity to create enough heat to melt the metals; when cooling down, the metals bind to one another. This method uses a welding power supply to create an electric arc between an electrode and the base material to melt the metals at the welding point. Though it is not suitable for pipe welding, it can be used for fabrication of steel structures.

MIG / MAG

Gas metal arc welding, also referred to as

metal inert gas welding (MIG) or metal active gas welding (MAG), is a welding process in which an electric arc forms between a consumable wire electrode and workpiece metal(s), which then heats the workpiece metal(s), causing them to melt and join. For MIG welding, the inert gas used is usually argon, helium or some mixture thereof. For MAG welding, CO2 is used, which reacts in the molten weld pool with the fusion joint. Along with the wire electrode, a shielding gas feeds through the welding gun, which shields the process from contaminants in the air. The advantage of these methods is faster welding and less slag.

Flame welding (oxy-fuel welding)

Oxy-fuel welding (commonly called gas welding in the U.S.) and oxy-fuel cutting, are

processes that use fuel gases and oxygen to weld and cut metals. A welding torch is used to

weld metals by heating two pieces to a temperature that produces a shared pool of molten

metal. Additional metal called filler is generally added to the molten pool (filler material

depends on the metals to be welded).

Oxy-fuel is one of the oldest welding processes, yet in recent decades almost all industrial uses have become obsolete due to the spread of various arc welding methods that offer more

consistent mechanical weld properties and faster application.

In

oxy-fuel cutting, a torch is used to heat metal to its kindling temperature. A stream of

oxygen is then trained on the metal, burning it into a metal oxide that flows out as slag.